Lathes are versatile machines that can be used for a variety of purposes. From turning wood into furniture to creating metal parts, lathes are a valuable tool in any workshop. However, before you make your purchase, it’s important to know a few things about lathes that can help you make an informed decision.

In this post, we’ll cover some of the key factors you should consider when buying a lathe machine. So read on to learn what to look for and how to get the best value for your money!

What is a Lathe Machine?

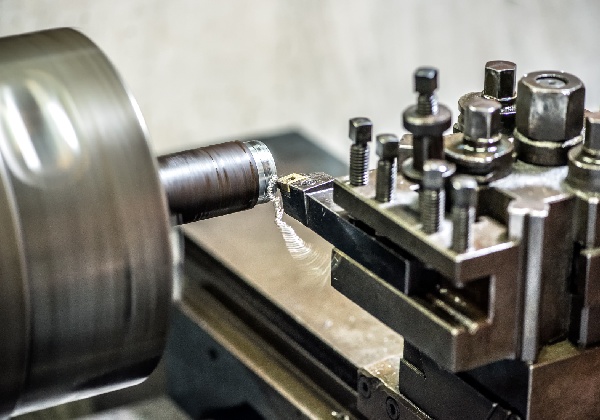

A Lathe Machine is a versatile machine that can be used to produce a variety of items, including furniture, construction materials, and even jewelry. It’s also known as an automatic turning lathe because it uses automated feeds and speeds to turn large pieces of metal or other material.

It has many applications, including the production of parts for aircraft and cars, firearms components, medical implants, and other objects. It can be used for a variety of tasks, such as turning wood or metal into objects such as toys, furniture, and other items. Lathes can be operated by hand or with power tools depending on the model.

10 Things to Know Before Buying a Lathe Machine

Here are 10 things you should know before buying a Lathe Machine:

Learn the Basic Lathe Machine Parts

Before you buy a lathe machine, it’s important to understand the different parts that make up this type of machine. Here are the most common ones:

The spindle: This is the main rotational component of the lathe. It usually has several different types of cutting edges and can turn around a variety of axes.

The cross slide: This slides along the spindle, allowing you to move the workpiece along its length. It also has several different types of cutting edges, which can be used to cut various materials.

The headstock: This connects to the cross slide and allows you to change the direction in which the workpiece is being moved.

The tailstock: This is located at the opposite end of the headstock and controls how much force is applied when turning the workpiece.

Ensure the Shop Has What You Need

Before you buy a lathe machine, it’s important to make sure that the shop you’re dealing with has the correct model and specs for what you need. Lathes can be very expensive, so it’s important to find a shop that will provide you with the best quality product possible.

Price Range Based on Size, Power, and Torque

Lathes can be classified by size (small, medium, or large), power (stepless or belt-driven), and torque (low, medium, or high).

When choosing a lathe machine, it’s important to consider your specific needs and the size of the project you plan to work on. You’ll also want to decide on the power and torque required for the type of lathe you choose. Finally, be sure to consult with a qualified technician to find the best lathe for your project.

The Durability Features

Lathes are often used in the manufacturing industry to produce parts or entire machines. They are very versatile machines that can be used to create various shapes and sizes, which is why they are so popular.

One of the things you need to know and consider when buying a lathe machine is its durability. Lathes can be very demanding on your equipment, and if it’s not properly maintained, it could end up costing you a lot of money in repairs or replacements. Make sure you check the machine’s specifications carefully before making your purchase.

Know the Size You Need

Before you buy a lathe machine, you need to know the size you need. Lathes come in different sizes, from small machines that can handle only a few pieces at a time to large machines that can work on entire car bodies.

It’s important to consider the type of work that you’ll be doing with your lathe machine. If you’re only going to use it for small tasks like turning small pieces of wood or metal, then a small machine is probably all you need. However, if you plan on using your lathe machine for larger projects like carving wooden sculptures or making large furniture pieces, then a larger machine will be more suitable.

Warranty and Customer Service

Another thing to keep in mind is the warranty. Most shops offer a limited warranty on their lathes, but this doesn’t always cover all of your needs. Make sure to ask about any additional warranties that may be available before buying.

Warranties usually cover defects in the machine itself and usually last for one year. However, some companies will offer longer warranties, while others may only offer guarantees on specific parts of the machine.

Customer service is also important when it comes to buying a lathe machine. Ideally, you want to be able to speak with someone who can help you resolve any issues that you might have with your purchase. If you can’t find a solution through customer service, then you may need to go ahead and take your machine in for repairs or replacements.

Inspect the Bed Ways

Before you buy a lathe machine, it’s important to inspect the bed ways. This will ensure that the machine is able to move the workpiece in a smooth and consistent manner. If there are any problems with the bed ways, the lathe won’t be able to produce accurate results.

The Spindle Speed, Horsepower, and Torque

Before you buy a lathe machine, it’s important to know the spindle speed, horsepower, and torque. These are the three most important factors when it comes to selecting the right machine for your needs.

The spindle speed is how many rotations per minute (RPM) the spindle on the lathe machine makes. The higher the spindle speed, the faster the material will be turned. This is important if you’re using high-speed materials like plastic or metal that need to be turned quickly.

The horsepower is how much power is being used to turn the material around the spindle. The higher the horsepower, the greater the amount of material that can be turned at once. This is important if you plan on using a lot of heavy materials or if you need to turn large objects quickly.

The torque is how much force is being applied by the motor to turn the material around the spindle. Higher torque machines use more power but also generate less backlash than lower torque machines. This means they’re easier to use and less likely to cause damage to your materials.

What Other Tools You Need Besides Lathe Machine

In addition to a Lathe Machine, you will need some other tools to help with your manufacturing process. Here are some of the tools. You don’t need to buy them all. Just buy what your machine demands to cut things smoothly. Some of the tools are:

Chamfering tool

Turning tool

Facing tool

Boring Bar

Grooving tool

Parting tool

Thread cutting tool

Know the Capabilities of Lathe Machines

Before you buy a lathe machine, it’s important to understand its capabilities. Lathes are versatile machines that can be used for a variety of tasks, such as turning wood, metal, or plastic into finished products.

Lathes can be used for a variety of different purposes, so it’s important to know which one is best suited for your needs. For example, a lathe machine that’s specifically designed for metalworking would be better suited for turning metals than one that’s only good for turning wood.

It’s also important to know the types of materials that can be turned with a lathe machine. Wood lathes are usually good for turning softwoods like pine and spruce, while metal lathes are better at working with harder metals like aluminum and steel.

Finally, it’s essential to know the dimensions of the materials that you’re going to be turning. Some lathes have capacity limits (in terms of weight and thickness) that you need to take into account when making your purchase decision.

Tips When You Buy a Second-Hand Lathe Machine

When you are looking at buying a second-hand Lathe machine, it is important to do your research. There are many factors to consider, including the type of lathe machine that you want and its features, like the carriage, headstock, tailstock, etc. You should also take into account the condition of the machine and whether or not there are any repairs that need to be made. Finally, make sure to ask for references from other buyers before making a purchase.

Why Do You Need a Lathe Machine?

A Lathe machine can be a great addition to your workshop if you are looking for ways to make intricate items or parts. This machine is used to turn objects by rotating them around an axis. It is perfect for creating things like bowls, tables, and other complex shapes.

Lathes also have a number of other uses, such as modifying the shape of existing pieces or making ornamental designs on products. They can even be used in production lines to create smaller items faster than traditional methods would allow.

So why not invest in one today? A Lathe machine may just become one of the most important tools in your workshop!

A Little History About Lathe Machine

Lathe machines have a long and illustrious history. The origins of the lathe can be traced back to the 13th century when the Egyptians invented the two-person lathe. And they quickly became popular for their ability to create precise parts out of wood.

Lathes are machines that were historically used in woodworking. They are similar to milling machines, but instead of cutting the material with a saw blade, the lathe rotates the tool around a central axis. This provides greater accuracy and control when making fine joinery ornaments or other parts of complex projects.

Lathes are still used today primarily for producing precision parts, but they can also be used for metalworking, jewelry making, and other industrial applications.

Types of Lathe Machines

There are many types of lathes that can be used in the manufacturing process. Some of them are CNC (Computer Numeric Controlled) lathes, manual Lathes, and Robotic Lathes.

CNC Lathes

CNC Lathes are the most popular type of lathe machine as they offer high-quality products at a lower cost than other types of machines. They use microchips to control several aspects of the machining process, including speed and direction. This allows for much more accuracy and precision when producing items such as parts or finished goods.

Manual Lathes

Manual Lathes may be less expensive than CNCLathes but tend to produce lower-quality results due to their lack of automation.

Robotic Lathes

Robotic Lathes use technology similar to that found in industrial robots, so they can handle complicated projects faster and with less wear on both equipment and workers’ hands.

Conclusion

Now you have read all the above-mentioned points and also understood what a lathe machine is all about. Thus, it’s time to dig deep into the market and find out some of the most efficient products available today. Take your time while buying one, as well as ensure that you use good quality material to make sure that your investment further rewards you in terms of output.

In case there are some questions left open, then feel free to ask us in the comments section below!

Lathe machines can be very useful in the workshop, but it is important to choose the right one for your needs. Read on to learn more about the different types of lathe machines available on the market and find the perfect one for your workshop.