If you are planning to read about CNC engraving, then this is the ultimate guide for you! In this article, we will provide you with the essential information you need to know about CNC Engraving. We will also discuss what types of CNC machines are used for engraving.

So, if you want to know about CNC engraving, this article will help you!

What is CNC Engraving?

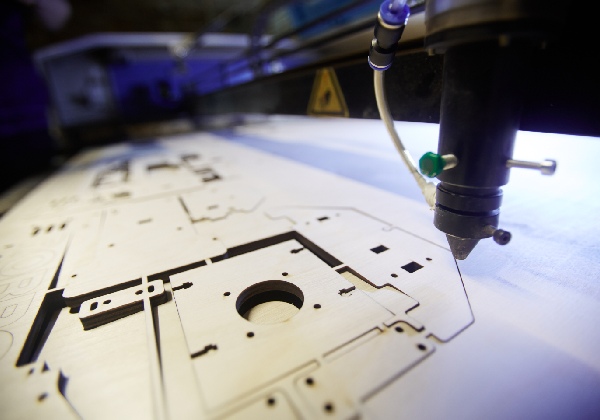

CNC engraving is the activity of machining metal or different materials utilizing a CNC (PC mathematical control) machine. In this cycle, the cutting apparatus is moved along an X, Y, and Z pivot to make many-sided designs in the material.

This strategy for etching is utilized for different applications, including modern parts creation, special signs, and custom gems making.

CNC engraving is exact and effective, permitting makers to deliver items rapidly and precisely. It likewise has the additional advantage of having the option to make complex shapes or plans without a lot of difficult work.

CNC engraving should be possible on practically any sort of material, including aluminum, steel, metal, copper, wood, acrylics, and froth.

The interaction can likewise be utilized to make custom logos or pictures on special items and publicize materials. With CNC engraving, you can tweak your item with an extraordinary plan that will stand apart from the rest.

Whether it’s for modern use or just to improve your image presence, CNC engraving can assist you with taking care of business.

What Type of CNC Machines Are Used for Engraving?

Laser Engraving Machine

Laser engraving machines are utilized to make brightening and practical things in different materials, including wood, metal, plastic, and glass. The lasers utilized in these machines can be set to various degrees of force and power contingent upon the material being engraved.

This empowers them to deliver itemized craftsmanship and accuracy markings effortlessly.

Laser engraving machines dispose of the requirement for actual instruments like saws, drills, and other hand devices. The laser engraving process is quick and proficient while likewise delivering consequences of a top-notch.

Laser etching machines are not difficult to work with and require minimal specialized information. They accompany easy-to-understand programming that makes setting up the machine and making fine art basic and direct.

This permits clients to begin rapidly with their laser engraving projects, pursuing the ideal decision for specialists and private companies the same. The expense of buying a laser engraving machine might be restrictive for some, yet there are numerous reasonable models accessible today.

CNC Router Engraving Machine

The CNC Router Engraving Machine can produce intricate shapes with high precision out of a range of materials. Wood, plastic, metal, and other materials, may produce delicate letters, logos, and patterns with detailed details.

These materials may be quickly and accurately cut and shaped with the machine.

It is, therefore, ideal for generating parts for custom designs, production parts, and prototypes. You can make one-of-a-kind goods that perform above expectations and withstand the test of time using a CNC Router Engraving Machine.

This machine is ideal for high-volume manufacturing runs because it is also incredibly dependable. It is the best option when trying to build intricate components for custom, production, or prototyping due to its speed and accuracy.

CNC Milling Engraving Machine

CNC milling engraving machines can be utilized for processing, boring, tapping, and different tasks in the machining business. It is additionally utilized in the development of accuracy parts like turbine cutting edges, clinical prostheses, and other complex parts.

These machines include high velocity and exactness with repeatability because of their exact command over the device.

They are equipped for performing unpredictable positions by cutting and molding materials in various structures.CNC milling engraving machines can be utilized for both manual and mechanized cycles and provide the most significant level of precision, repeatability, and unwavering quality.

Moreover, these machines are outfitted with cutting-edge programming that makes it simple to program complex cuts and shapes precisely and rapidly.

What’s more, they are likewise furnished with many adornments that empower administrators to tweak the cycle as per their necessities. CNC Processing Etching Machines are a fundamental piece of the metalworking business and can assist organizations with expanding efficiency, diminishing costs, and working on quality control.

They are likewise an extraordinary decision for specialists as they permit clients to make modified parts and plans effortlessly.

With the right machine and extras, CNC Processing Etching Machines can be utilized to make dazzling activities rapidly and without any problem.

CNC Engraving Tools

V-Bit

A V-bit is a kind of cutting device utilized in CNC (PC mathematical control) engraving machines. It is molded like the letter “V” and is utilized to make point-by-point etchings and lettering on materials like wood, metal, and plastic.

The point of the Angular shape decides the width of the cut, and the sharpness of the tip decides the degree of detail that can be accomplished.

V-bits can be utilized for both roughing and completing tasks and can be produced using different materials like strong carbide, high-velocity steel, or precious stone covered. They are ordinarily utilized related to a collet to hold the device set up and offer vital help during the cutting system.

Engraving Cutters

Engraving cutters and pieces are utilized to cut into metal or other hard materials. They arrive in different shapes and sizes and can be utilized for both level and three-layered etching. Engraving devices are accessible in carbide, jewel, rapid steel, and cobalt.

CNC engraving machines utilize these apparatuses to make multifaceted examples and shapes with accuracy. They are great for making logos, signs, identifications, and names. Experts use them to make special plans that can be utilized in different applications.

CNC engraving is a fundamental piece of numerous enterprises, including gems making and modern assembling.

Ball End Mills

Ball end factories are flexible CNC engraving devices for making different shapes and surfaces. The ball end factory makes a round or circular shape on the workpiece’s surface and is utilized to make bent surfaces and complex highlights like curves, furrows, channels, and pockets.

Ball end factories are accessible in various sizes, woodwind lengths, and neck lengths, so they are appropriate for an extensive variety of etching applications.

They could be utilized to make shallow pockets and little forms on the workpiece. CNC engraving with ball end processes, for the most part, requires more modest stepover distances than level-end plants, bringing about smoother cuts with less instrument wear.

What Materials Can You Engrave?

Metal

Metal is one of the most well-known materials for engraving because of its toughness and adaptability. It tends to be engraved utilizing various techniques, including laser etching, substance scratching, and mechanical etching. From there, the sky is the limit.

Its surfaces can be left with a finished completion or cleaned to a splendid sheen.

With metal, subtleties can be finely scratched and perplexing plans made. Various kinds of metals respond diversely to each etching technique, so involving the right one for your project is significant.

Wood

You can engrave wood with a laser engraver. Wood is a natural material that is made out of cellulose filaments. It is lightweight and simple to work with, settling on it a well-known decision for laser etching projects.

Its normal grain creates each undertaking remarkable, and its surface can be effectively cut into perplexing plans. Wood can likewise endure changes in temperature and stickiness, so it makes an optimal vehicle for tough etchings.

Plastics

Engraving plastic materials is turning out to be progressively well-known as a method for redoing or customizing things and making interesting bits of workmanship. The cycle includes utilizing a drill, like a Dremel, to scratch pictures or text into the material.

This strategy enjoys many benefits, including the capacity to make complicated subtleties and enduring outcomes that won’t blur or erode like different techniques.

Moreover, engraving should be possible rapidly and effectively with negligible arrangement time. With the right information and instruments, anybody can utilize this technique to make shocking bits of craftsmanship from various materials.

Coated Materials

Engraving can be an incredible method for adding personalization and style to any covered material. Covered materials are ideally suited for engraving, as the covering gives a defensive layer that makes it more straightforward to clean and takes into consideration complex plans. With the right apparatuses, you can make custom pieces for gifts or unique events.

Whether you’re utilizing a laser shaper or hand-held etcher, there are a lot of methods and materials that permit you to get imaginative with your ventures.

Leathers

Leather engraving is an artistic expression that has been around for quite a long time and is as yet famous today. It includes the utilization of apparatuses to make examples, words, and plans on calfskin material.

The cycle frequently begins with a layout or guide being made which frames where certain markings ought to be made, trailed by exact cutting and afterward shining or coloring strategies to feature the recently made example or plan.

Leather engraving can be utilized to make anything from customized gifts to custom coats or furniture.