If you are planning to buy a CNC machine, then this is the ultimate guide for you! In this article, we will provide you with the essential information you need to make an informed purchase. We will also outline the different types of CNC machines on the market and explain their special characteristics in detail.

So whether you are a beginner or an experienced machine user, this guide will have everything you need to know!

What is a CNC Machine?

A CNC machine is a computer-controlled machine that can be used to create precise pieces of metal or other materials. CNC machines are often used for tasks such as cutting metal parts, forming plastic objects, making cuts in woodworking items (such as table legs), and more.

They operate using either manual or automated procedures depending on the type of CNC machine being used.

Recently, there has been growing interest in using CNC machines for tasks such as 3D printing and fabricating custom furniture. By being able to create customised pieces quickly and easily, this technology has the potential to revolutionise many industries.

Benefits of Using CNC Machine

A CNC machine can be a great way to improve your productivity and efficiency in the workplace. It allows you to quickly and easily design intricate objects or patterns using Computer-aided Manufacturing (CAM) software.

This technology has become increasingly popular due to its many benefits, including increased accuracy, speed, and consistency. Additionally, the ability to update designs quickly means that you can keep up with ever-changing industry trends.

And lastly, because CNC machines are portable, you can take them where you need them – even onsite in your production line!

What Materials Can a CNC Machine Cut?

Here are some of the materials that a CNC machine can cut:

- Wood

- Plastics

- Acrylic

- Foam

- MDF

- Glass

- Brass

- Stone

- Aluminium

- PVC

- Copper, etc

In What Ways Can CNC Machines Be Applied?

Here are the versatile application possibilities of the CNC Machine:

- 3D Carving

- 2D Carving

- Furniture Making

- Door Making

- Decorations

- Acrylic Fabrications

- Aluminium Fabrication

- Woodworking

- Cabinet Making

- Exhibit & Fixtures, etc

Tools Need Along to Run a CNC Machine

- End Mill

- Drill Bits

- Reamers

- Face Mill

- Thread Mill

- Slab Mill

- Fly Cutter

- Gear Cutters

- Hollow Mill, etc

Types of CNC Machine

There are so many types of CNC Machines available on the market nowadays. Some of the common CNC machines are:

CNC Milling Machine

CNC mills are a type of industrial machine that uses computer-controlled motions to create parts from solid materials. They are often used in the manufacturing process for things like aircraft parts, car components, and medical equipment.

The milling process starts by receiving a 3D model of the part or object that is being created. From this CAD file, the CNC mill will determine how many pieces need to be cut out of the raw material and then generate precise coordinates for each one.

Uses

CNC milling machines are versatile tools that can be used to create parts from a variety of materials. They are commonly used in manufacturing industries to create components such as gears, moulds, brackets, and even entire products.

They have also become popular among hobbyists who want to make custom items from scratch.

CNC milling machines come in both manual and automatic versions, so it is important to choose the one that best suits your needs. Manual mills typically require more skill than automated units do but are less expensive overall since they don’t require continuous monitoring by a computer operator.

Automatic mills tend to be more expensive up front but offer greater flexibility thanks to their ability to maintain constant alignment between the robot’s cutting head and movable workpiece(s).

CNC machines are even useful for making customized items such as jewellery, weapons, furniture, etc., which could not otherwise be manufactured economically or at all using traditional manufacturing processes.

Key Features

The main features of a CNC milling machine are as follows:

- Precise, automated movements that result in accurate cuts

- Robotic arms that can handle even the most delicate and difficult shapes

- Parts that are accurately dimensioned and fit together perfectly.

- Fast and efficient, so they can easily produce multiple parts per minute.

CNC Lathe machine

A CNC lathe machine is a type of machine that uses computer numerical control (CNC) technology to turn parts and assemblies. It is similar in operation to a rotary tool, but with one key difference: it can move the workpiece around on a spinning axis instead of just rotating the tool around its own axis.

This makes it possible to produce parts with very tight tolerances, which is beneficial in a variety of applications.

The basic operation of a CNC lathe machine is simple: You input the dimensions of the part you want to create, and the machine then starts rotating randomly around its central axis.

As it does so, it cuts the part out of the material using extremely high-speed rotary blades. This process is repeatable, which means you can create multiple copies of the same part with ease.

Uses

One of the most common uses for CNC lathes is in the manufacturing of firearms. And because CNC lathes are so precise, they are often used in industries like automotive manufacturing and aerospace engineering.

Additionally, they are also popular among hobbyists and DIYers who want to create unique items or decorations for their homes or workplaces.

Key Features

Here are the key features of a CNC lathe machine:

- It has precision so that you can create high-quality objects accurately.

- It has a wide range of applications, including engineering, construction, and manufacturing.

- It’s easy to use and control, making it perfect for skilled users.

CNC Grinders

A CNC grinder is a machine that uses rotational motion to cut or grind materials. The machine has two main sections: the motor and the grinding wheel. The motor spins the grinding wheel at high speeds, which grinds the material into tiny pieces.

This process is repeated continuously until the material has been reduced to its desired form. This makes it a useful tool for a variety of purposes, including manufacturing parts and components, producing finished products, and creating custom items.

There are different types of CNC grinders available on the market today, each designed for specific applications or uses.

Uses

CNC grinders are used mostly in the manufacturing industry. But they have started to become popular in other creative fields as well.

Artists, architects, and fashion designers use them to create intricate pieces of jewellery, furniture, and accessories. They also play a major role in the production of high-quality 3D models.

Key Features

Some key features of a CNC grinder include:

- It has high precision and accuracy, meaning that the finished products will be of great quality.

- It’s very fast and easy to use, making it ideal for small batches or short runs.

- It can handle a wide range of materials, making it perfect for various applications.

CNC Drilling Machine

A CNC drilling machine is a type of robot that is used to make precise, accurate holes in various materials. It consists of several moving parts, including a drill bit, a milling head, and a control system.

The drill bit is placed inside the material to be drilled, and the machine guides it through the material using speed and direction controls. The milling head moves around the drill bit in order to create the desired hole shapes. This process is repeated until the hole is complete.

Uses

CNC drilling machines are used to drill holes in various hard materials, including stone, wood, and concrete. They work by using a computer program to control the direction, speed, and angle of rotation of the drill bit. This makes it possible to produce accurate and precise holes in difficult materials.

Key Features

Here are some key features of a CNC drilling machine:

- It has multiple heads that allow it to drill through different materials with precision.

- It has an automatic feeding system that ensures the material is fed into the drill bit at the correct speed and angle, ensuring accurate drilling.

- The machine is equipped with sensors that help avoid unwanted accidents, such as damaging walls or floors.

CNC Electrical Discharge Machine (EDM)

EDMs use a high-frequency current to cut or grind materials. It works by moving the material around using a series of sharp blades, which are powered by electricity. This is how it is able to create complicated and intricate shapes and patterns in materials like wood, metal, plastic, and other soft materials.

The main advantages of using a CNC Electrical Discharge Machine are that it is fast and efficient. Additionally, it doesn’t require any special training or skill to operate, and it can be used for both small-scale and large-scale projects.

Uses

CNC Electrical Discharge Machines are used for a variety of tasks, such as machining parts, fabricating components, and cutting materials. They are also used in the manufacturing of electronic equipment and other industrial applications.

Key Features

There are several key features that make an EDM an excellent choice for various applications:

- They are precision tools capable of producing high-quality parts with little variation in accuracy or quality.

- They are fast and efficient machines, capable of cutting through large pieces of material quickly and without wasting any time.

- They are versatile machines, able to handle a variety of different materials and shapes.

CNC Plasma Cutter

A CNC Plasma Cutter is a sophisticated machine that uses high-powered beams of plasma to cut materials like metal and plastic. The beams slice through the material with extreme accuracy, which makes it a very versatile tool for cutting different types of materials.

The main advantage of using a CNC Plasma Cutter over other types of cutting tools is that it is very fast and accurate. This means that you can quickly and easily create intricate designs or patterns in your materials without having to worry about mistakes.

Additionally, the high-powered beams also make it possible to cut through hard materials like metals and plastics without damaging them.

One downside of CNC Plasma Cutters is that they are quite expensive to purchase and operate, which means that they may not be suitable for everyone.

Uses

This machine is extremely versatile and can be used for a wide range of tasks, including cutting shapes out of metal plates, creating intricate designs in metal sheeting, and even making cuts into other materials like plastic.

Features

There are a few amazing features of the CNC Plasma cutter. Which are:

- They are faster and more accurate than traditional cutting machines.

- They are versatile and can be used for a variety of purposes, such as fabricating parts or creating detailed designs.

- They are less likely to cause injury or damage to the material being cut.

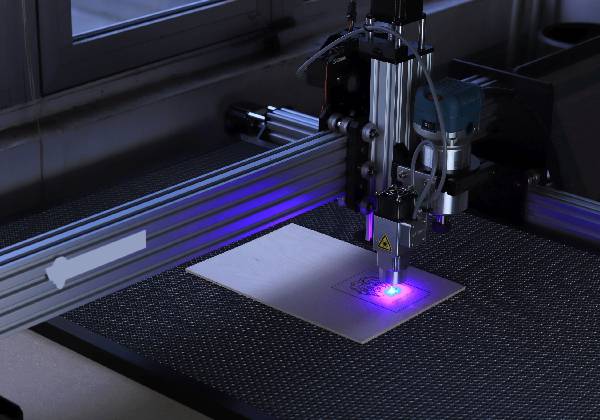

CNC Laser Cutter

CNC laser cutters use a series of lasers to carve parts out of materials like wood, plastic, and metal. The lasers either heat up the material so that it melts and can be carved, or they break down the material into small pieces so that the lasers can cut through it easily.

The great thing about CNC laser cutters is that they’re incredibly accurate and easy to use. You simply put the material you want to cut onto the movable bed of the machine and set the cutting parameters using the on-screen controls. Then, just relax and let the machine do its job!

Uses

CNC laser cutters are perfect for a variety of applications, including woodworking, manufacturing, and even jewellery making. They’re also versatile enough to be used in a variety of different formats, including standard 2D and 3D drawings.

Because they’re so versatile, CNC laser cutters are perfect for any project that requires precision and clean cuts.

Key Features

Some of the key features of a CNC laser cutter include:

- The ability to cut intricate shapes and patterns with precision.

- The ability to produce high-quality parts in a short amount of time.

- The ability to easily change the dimensions of your parts.

- -The ability to easily create 3D objects.

CNC Router

A CNC router is a machine that enables you to create complex three-dimensional objects by moving a series of cutting tools called Cutters around a surface.

The machine uses a computer to control the movement of the cutters, and it can produce intricate details that are impossible to achieve using other methods.

There are several types of CNC routers, but they all share the same basic principles. They all have an input device that allows you to feed in the design file (usually in CAD or 3D printing format), and then the machine takes care of everything else – directing the cutters where they need to be and making sure that the finished product is accurate and consistent.

Uses

Some of the most common uses for a CNC router include manufacturing parts, creating patterns, and modifying existing objects. It is also perfect for use in the dental industry, as it can be used to create custom dentures and other dental implants.

Key Features

Some of the amazing features that a CNC router has are:

- It’s versatile – CNC routers can be used for a variety of tasks, from simple woodworking projects to more complex projects like car bodies or furniture.

- It’s fast – CNC routers are much faster than traditional woodworking tools, which makes them ideal for speedier tasks like manufacturing.

- It’s accurate – Unlike traditional woodworking tools, which can be inaccurate when working with delicate materials or curves, CNC routers are very precise and reliable.

3D Printer

A 3D printer is a machine that can create three-dimensional objects from a digital file. It works by depositing layers of material Built by the computer to create the object you want.

It uses a variety of filaments, such as plastic, metal, and even food.

To print an object using a 3D printer, the user first creates a digital model of the object on a computer. This model is then sent to the 3D printer, where it is used to create the object’s physical form by printing out small pieces of the model. These pieces are then combined together to create the finished product.

Uses

3D printers are used for a variety of purposes, but some of the most common ones include printing objects from 3D files, printing replacement parts for electronic devices, and manufacturing prototypes.

Key Features

There are many different types of 3D printers, but all share some key features. These include:

- The ability to print in multiple colours.

- The ability to print using multiple filaments (including flexible filaments).

- The ability to produce high-resolution prints.

- The ability to create detailed parts with intricate details.

Important Considerations When Buying Any Cnc Machine

When you are looking to buy a CNC machine, there are many important considerations that you should take into account. These include the type of machine that you want, the features and specifications of the machine, your budget restrictions, and your technical skills.

When choosing a CNC machine, it is important to consider what type of work you will be using it for. Some machines are designed specifically for manufacturing or fabricating parts, while others may be better suited for design tasks such as 3D printing or designing patterns.

It is also essential to factor in how much money you have available to invest and what kind of technical knowledge you possess. Some machines require extensive programming expertise, while others can be operated via basic commands with little training required.

Once all these factors have been considered, it becomes easier to narrow down which specific CNC machine would best suit your needs and skill level. In addition to finding an appropriate model for use at home or office space, always get professional installation if necessary!

This way, everything goes smoothly from start to finish when making this big investment.

Want to buy a CNC machine? Here’s a buyer’s guide of CNC machines that will help you understand the different types, uses, and features of machines.