If you’re thinking about getting into cutting or fabricating with a laser or CNC machine, it’s important to understand the difference between the two. In this article, we’ll go over the main features of each technology, as well as the benefits and drawbacks of each.

Ultimately, the choice between CNC and laser cutting will come down to your specific needs and preferences. So read on to learn all you need to know!

What is CNC Cutting?

CNC cutting is a process used in manufacturing that uses computers to control the movements of tools and machine components. This technology is often used to create parts or products that are architecturally precise and require high levels of accuracy.

Common applications for CNC cutting include machining materials such as metals, plastics, and composites, fabricating parts for industrial equipment, making prototypes or samples, and creating 3D models.

Common Uses of CNC Machines

As technology continues to evolve and become more affordable and user-friendly, many businesses are beginning to use CNC machines in their production processes. This allows them to save time and money by creating custom components rather than using off-the-shelf options or piecing together different pieces manually.

Additionally, it enables them to reduce waste by producing parts with exact specifications instead of substandard ones that may not meet all requirements.

Some of the most common uses for CNC machines include manufacturing, engineering, medical devices, automotive components, jewellery making, and more. Because they are so versatile and capable of producing high-quality results quickly and efficiently, CNC machines are becoming increasingly popular in both commercial and residential settings.

Advantages of Using CNC Machine

Accuracy

CNC machines are incredibly accurate, meaning that they can create highly precise objects without any error. This is a huge advantage when it comes to creating items that require precision, like medical equipment or prosthetic limbs.

Another advantage of CNC machines is that they are relatively easy to learn how to use. This makes them a great choice for businesses or entrepreneurs who want to start their own manufacturing business.

Versatility

CNC machines are versatile and efficient tools that can be used for a variety of purposes, including manufacturing. They allow you to automate portions of the manufacturing process, which saves time and energy. Additionally, they can produce high-quality products faster than traditional methods.

Safe

Another advantage of using CNC machines is that they’re safe – even when used by inexperienced users. Unlike manual tools, CNC machines don’t require you to touch or move them around in order to ensure safety.

In fact, most models come with safety features like auto-stop and emergency stop systems that help protect you from accidents.

Speed

One of the main advantages of using a CNC machine is its speed. You can often produce high-quality products much faster than you could with traditional methods.

This makes it a valuable tool for manufacturers who need to make rapid changes to their products or who want to create custom components quickly and without any fuss.

Disadvantages of Using CNC Machine

There are a few disadvantages to using CNC machines, but they generally outweigh the advantages. Here are some of the most common disadvantages:

- They are pretty expensive.

- They require extensive knowledge about machine tools and how they work, which can be difficult for someone who’s just starting out in the industry.

- They’re difficult to move around and require a lot of space.

- It can be hard to find qualified technicians who know how to operate them correctly.

What is a Laser Cutter?

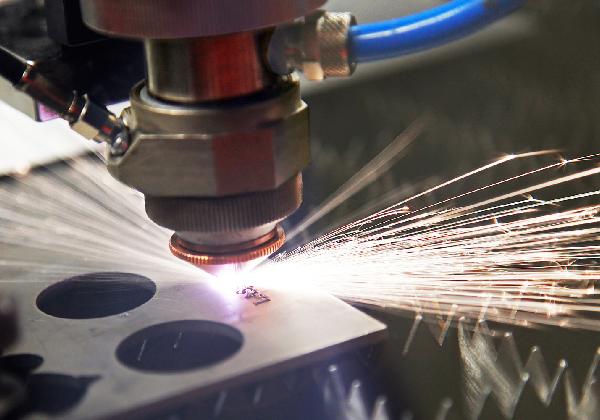

A laser cutter is an incredibly versatile machine that can be used to create intricate designs and patterns out of plastic, metal, or other materials. In a nutshell, it uses lasers to cut through the material – quickly and easily. This type of machine is perfect for creating prototypes or high-quality copies of documents or objects.

Lasers are also great for cutting through tough surfaces like glass and wood without causing damage. So if you’re looking for a new way to create beautiful effects in your work or life, consider investing in a laser cutter!

Common Uses of Laser Cutter

Laser cutters are often used in the manufacturing and construction industries to create custom parts or products. They can also be used for signage, signs, labels, packaging, and more.

Some of the most common uses of a laser cutter include creating logos or designs from scratch, cutting out components for machines, making patterns for fabricating objects such as furniture, and cutting glass into precise shapes.

Advantages of Using Laser Cutters

Flexibility

Laser cutters are extremely flexible and can be used for a wide variety of purposes. They’re often used in the manufacturing industry, but they can also be used to create intricate designs and patterns for furniture, clothes, housewares, and a variety of other products.

Accuracy

One of the main advantages of using laser cutters is that they’re very accurate. This means that you can produce high-quality products without having to worry about mistakes or inconsistencies.

In addition, laser cutters are also quick and easy to use, making them ideal for small businesses or individual entrepreneurs who want to start their own businesses.

Contactless Cutting

Laser cutters are becoming increasingly popular due to their advantages over traditional cutting methods. One of the biggest advantages is contactless cutting, which is when the laser beam cuts the material without actually making physical contact with it.

This means that the cutter can move around more freely, making it faster and easier to create intricate designs.

Eco Friendly

Another advantage of laser cutters is that they’re eco-friendly. They don’t produce any fumes or hazardous waste, and they use a fraction of the energy of other cutting methods. In fact, some models even have a built-in cutter dust collector that helps reduce noise and messes.

Quality

Laser cutters are a great way to produce high-quality products quickly and accurately. They use lasers to cut sheets of metal or other materials. The lasers are very precise and cause the material to cut through easily without damaging the surface.

This makes laser cutters a great option for products that need to be precisely tailored, like furniture or clothing.

Disadvantages of Using Laser Cutters

However, there are a few disadvantages to using a laser cutter.

- First and foremost, they can be very time-consuming to use. You’ll need to be patient while the machine cuts the material, and you’ll also need to make sure that the material is correctly positioned on the machine so that it will be cut accurately.

- Second, laser cutters can be dangerous if not used correctly. If you’re not careful, you could end up injuring yourself or damaging your machine.

- Finally, laser cutters can be quite expensive compared to other tools available on the market.

Difference Between CNC Cutting & Laser Cutting

There is a big difference between CNC (Computer Numerical Control) cutting and laser cutting, but both methods have their benefits. With CNC cutting, the tool precisely traces out an outline of what you want cutting on a piece of material using small rotary tools with high speeds.

This approach is often used for more detailed or intricate cuts that are too difficult or time-consuming to be done with other types of machines.

Laser Cutting, on the other hand, uses powerful lasers to create precise lines and curves in materials without involving any physical contact between the object being cut and the machine tool. This eliminates Accuracy Limitations caused by conventional machining techniques where punching bits into pieces can cause distortion due to differences in metal thicknesses across different parts of an object.

Laser Cutters are also able to quickly produce multiple copies of the same objects superimposed upon one another, which adds value when it comes to product design & production.

Which Process is Better for You?

It really depends on the specific job that you are trying to do. Both have their benefits and drawbacks, so you need to consider your specific needs before making a decision.

CNC Cutting typically results in a higher level of accuracy and precision, while Laser Cutting can be faster but may not yield as high a level of accuracy. Additionally, both methods require special equipment that must be calibrated regularly in order to produce consistent results. So, whichever process you choose will likely involve some investment up front.

In terms of aesthetics, CNC cutting often produces greater levels of detail than laser cutting does. However, laser cutting can sometimes achieve more realistic textures or images that are closer to reality than those produced by CNC machines.