Milling machines can be a costly investment, and it’s important to do your research before making a purchase. That’s why we’ve put together a list of things to look for when buying a used milling machine.

This will help you avoid making any costly mistakes and ensure that you get the most value for your money. So what are you waiting for? Check out the list and start making your purchase today!

When Does It Make Sense to Buy a Used Milling Machine?

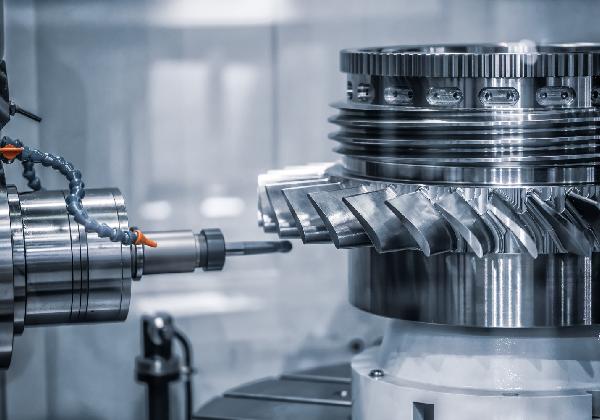

Buying a used Milling Machine can make sense if you’re looking for an affordable and reliable option. This type of machine is often used in manufacturing, food processing, and other industrial applications.

Therefore, it is likely that the machine will be in good condition and has been well-maintained over time. Furthermore, buying a used milling machine can potentially save you money compared to purchasing a new one.

Keep in mind that not all machines are suitable for use as milling machines. Before making your purchase, be sure to ask the seller questions about the specific model you’re interested in so that you know whether or not it’s viable for your needs.

Additionally, check out online reviews to get an idea of how people have treated this type of equipment before purchase.

You’ll Probably Look for One of These Milling Machines:

- CNC Milling Machine

- Horizontal Milling Machine

- Vertical MillingMachine

- Bed Type Milling Machine

- Universal Milling Machine

What to Look for When Buying Your Used Milling Machine?

Is the Machine Manual or CNC Controlled?

When you’re shopping for a used milling machine, it’s important to determine whether it is manual or CNC controlled. This type of mill is typically less expensive than CNC mills, but it’s also less accurate and can produce inferior products.

CNC mills, on the other hand, are operated by a computer system that controls all the machinery within the mill. They’re more expensive than manual mills, but they’re often much more accurate and produce high-quality products.

The Machines Size & Weight

When buying a used milling machine, it’s important to make sure that the machine is the right size and weight for you.

Typically, milling machines come in different sizes and shapes. If you’re planning on using the machine in a small space, then a small milling machine will be perfect. However, if you need the capacity to handle larger pieces of wood or metal, then a large milling machine might be better.

Machines Table Size

When you’re shopping for a used milling machine, it’s essential to pay attention to the machine’s table size. This is the area on which the workpiece is held while it’s being milled.

A good working surface should be slick so that the wood or plastic doesn’t stick and cause inaccuracies in the finished product. In addition, this will determine how large a workpiece can be put into the machine and milled.

If you’re looking to mill small pieces of wood or plastic, a table size of 2″x2″ or smaller will be sufficient. If, on the other hand, you plan on using your milling machine for larger pieces of wood or plastic, you’ll need to purchase a machine with a table size of at least 4″x4″.

Does the Machine Have Warranty?

When purchasing a used milling machine, it’s important to ask about the machine’s warranty. This will give you peace of mind in case something goes wrong with the machine, and you need to get it fixed or replaced. Make sure that the warranty covers both mechanical and electrical failures, as well as any damage that may be caused by misuse.

The Saddle, Longitudinal, and Knee Travel Limits

When buying a used milling machine, it’s important to be aware of the longitudinal(X-axis), saddle(Y-axis), and knee travel limits(Z-axis). These are the three axes that determine how tricky dimensions & typical workpieces the machine can handle. Or else the whole time will be gone just to reach the entire work surface.

Spindle Speed

One of the most important factors to consider is the spindle speed when you buy a used milling machine. This is the speed at which the spindle moves, and it’s essential in order to get accurate results when milling materials.

Some mills come with multiple spindle speeds, allowing you to adjust them as necessary. Others have a fixed spindle speed that you need to accept before using them. If you’re not sure what your spindle speed is, be sure to ask the seller or check the documentation that came with your machine.

The Sellers Validity

Another important thing you need to do is evaluate the seller’s validity while buying your second-hand milling machine. This means checking to see if they’re registered with the relevant authorities, have a valid insurance policy, and are reputable in the community.

You can also check to see if they’ve been around for a long time and whether they’ve had any negative feedback in the past. It’s also worth checking out their customer ratings and reviews to get a sense of how reputable they are.

Ultimately, it’s important to make sure that you’re buying from someone who you trust and whose business is good quality.

The Price

It’s important to be mindful of the machine’s price. This is because the cost of a used milling machine can vary considerably based on its make and model. Therefore, it’s important to do your research first to find out what kind of price range you’re comfortable with.

Compare if the Price is Lower Than the Newer Milling Machines

Secondhand products are typically much cheaper than newer ones. Because they’ve been used and might not be in the exact fresh condition as they were on the first purchase.

So, in order to make the most out of your money, you need to make sure that your used milling machine costs lower than any brand-new milling machine. Or else you could’ve simply bought any brand new machines if both used and newer ones cost the same.

The Availability of Spare Parts for the Machine in the Future

When buying a used milling machine, it’s important to factor in the availability of spare parts in the future. This is because if there are no spare parts available, you’ll be forced to either buy a new machine or find an alternative way to use the machine.

Therefore, it’s important to ask the seller about their policy on spare parts and whether they have any that can be used in the future.

How’re You Gonna Receive Your Product?

Finally, when you buy your secondhand milling machine, it’s an important factor in the logistics to consider how you’ll be receiving your product. You should make sure to discuss this with the seller in advance so that they know what to expect and can prepare for any necessary repairs or adjustments.

Is Buying a Used Milling Machine Worth It?

Buying a used milling machine can be a great investment if you are able to find the right one. This type of equipment is often in high demand and has a lifespan that stretches far beyond the standard five- or six-year period.

Plus, because they’re often well-maintained, used milling machines typically work better than new ones do when first installed.

When shopping for a used milling machine, it’s important to investigate the condition of both the machinery itself and its accompanying parts. Also, make sure to get an estimate on how much maintenance will be required over its lifetime (this includes scheduled tune-ups as well as repairs).